Business Overview

Coating

Wadayamaseiki Co.,Ltd

>Business Overview >Coating

Along with the increasing speed of mold production and the diversification of PVD coating, the latest coating equipment was installed and PVD coating services began in 2013.By combining this with our original mirror polishising method that has been cultivated over the years we have been able to improve the performance of our molds.

Due to our consistent quality control standards we can suggest the most appropriate and unique coating for each and every mold in order to improve performance.

Due to our consistent quality control standards we can suggest the most appropriate and unique coating for each and every mold in order to improve performance.

Theory behind PVD and Coating Methods

PVD (Physical Vapor Deposition) is a physical coating method in which the material used as the coating is heated in a highly pressurized environment (10-1〜10-5Pa). The coating material is evaporated into small particles (atoms, molecules, ions, etc..) using an electron beam, holo cathode, arc discharge, or sputtering and is then sprayed on the surface of the substrate.

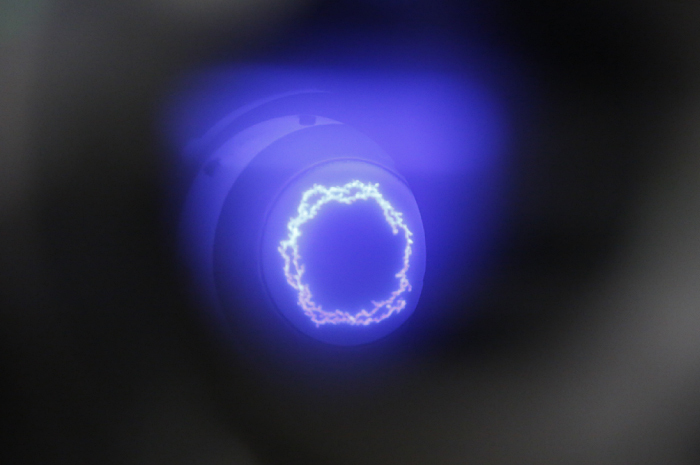

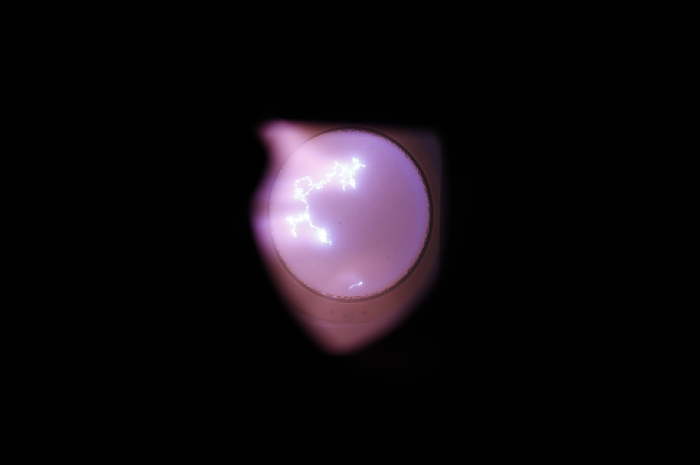

Electron beams, holo cathodes, and arc discharge are becoming more widely utilized methods of PVD for molds. Comparatively speaking the hollow cathodeand electron beam methods generally produce smoother surfaces; however, depedning on the raw materials used to make certain alloys coating using those methods is not possible. Therefore the arc discharge method is becoming more widely used.

At Wadayama Seiki we also utilize a special method in which the strength of the bonding is higher, called improved arc discharge ion plating.

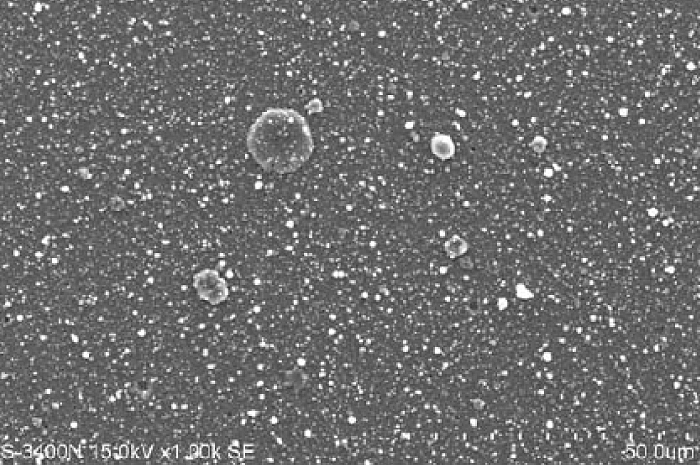

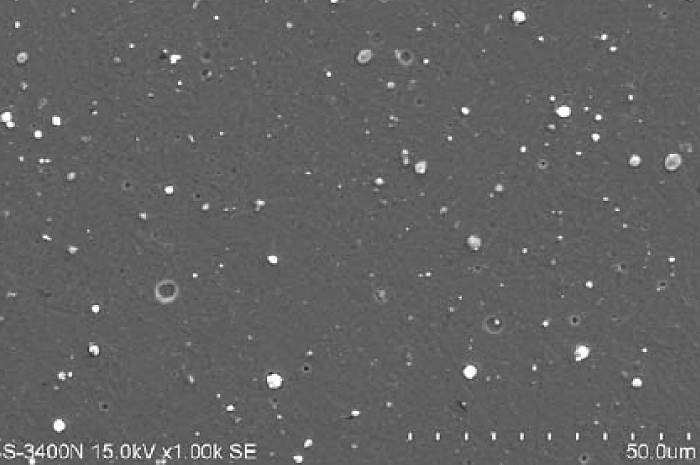

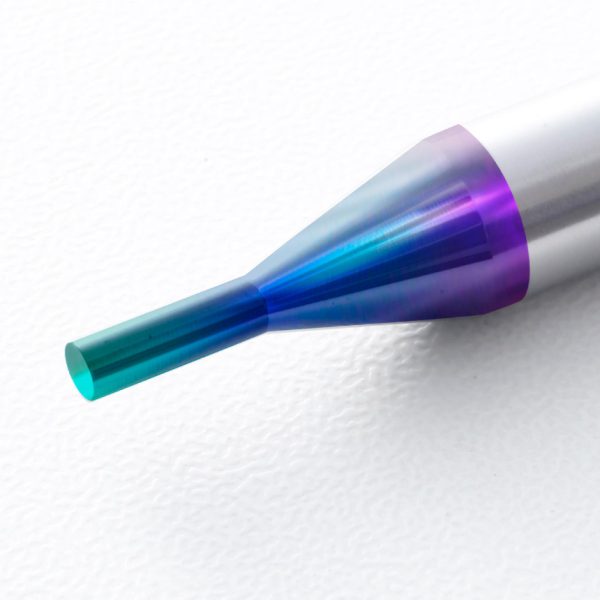

In normal arc discharge ion plating small metal particles known as droplets are unavoidably mixed in with the coating (Figure 1). These droplets cause surface irregularities to arise, and are the basis for adhesions.Typically, protrustions on the surface are smoothed out through the process of polishing which takes place after the coating. However, even if the protrusions are removed small amounts of droplets are lost which create small crevaces. in the same way as the protrusions, the creavaces also lead to surface irregularites; therefore, it is important to minimize the amount of drop plates within the coating as much as possible. However at Wadayama Seiki we use a special arc evaporation source which is able to efficiently reduce the amount of these droplets. This allows us to create a smoother surface than the normal arc discharge ion plating method used up until this point (Figure 2). Furthermore, by polishing the mold's surface after the coating we can create the optimum surface condition.

Electron beams, holo cathodes, and arc discharge are becoming more widely utilized methods of PVD for molds. Comparatively speaking the hollow cathodeand electron beam methods generally produce smoother surfaces; however, depedning on the raw materials used to make certain alloys coating using those methods is not possible. Therefore the arc discharge method is becoming more widely used.

At Wadayama Seiki we also utilize a special method in which the strength of the bonding is higher, called improved arc discharge ion plating.

In normal arc discharge ion plating small metal particles known as droplets are unavoidably mixed in with the coating (Figure 1). These droplets cause surface irregularities to arise, and are the basis for adhesions.Typically, protrustions on the surface are smoothed out through the process of polishing which takes place after the coating. However, even if the protrusions are removed small amounts of droplets are lost which create small crevaces. in the same way as the protrusions, the creavaces also lead to surface irregularites; therefore, it is important to minimize the amount of drop plates within the coating as much as possible. However at Wadayama Seiki we use a special arc evaporation source which is able to efficiently reduce the amount of these droplets. This allows us to create a smoother surface than the normal arc discharge ion plating method used up until this point (Figure 2). Furthermore, by polishing the mold's surface after the coating we can create the optimum surface condition.

Figure 1:Surface made using normal arc discharge ion plating.

|

Figure 2:Surface made using the improved arc discharge ion plating.

|

Merits of PVD

In order to increase the abrasion and adhesion resistance of a mold's ceramic coating, CVD (Chemical Vapor Deposition) or PVD (Physical Vapor Deposition) is frequently used. Recently, PVD in particular has rapidly grown in popularity. Some of the reasons for that are listed below.

- ■ Low Temperature Processing

- Due to a relatively low temperature (around 250°C~450°C) which is below the tempering temperature of steel)used in PVD coating, the form of the mold experiences little to no change. In PVD the error in accuracy of dimensions is less than 0.01mm: however in CVD the error in accuracy of dimensions is generally higher than 0.01mm. Furthermore, PVD coating due to the dense strucuture the coating hardness increases compare to CVD coating.

- ■ Surface stress

- In contrast to PVD coating, which leaves compressive stress; CVD coating due to the differences in the thermal exapnsion coefficient of the substrate and the ceramic coat, leaves tenisle stress. Due to this tensile stress cracks easily form on CVD coated surfaces compard to PVD coated surfaces.

- ■ Size Control

- In PVD depending on the shape of the mold, the coating thickness is uneven. In the case of processing the inside diameter of a mold, the thickness surrounding the mouth has a tendency to become thicker, making processing the inside diameter difficult. However, recently we have become able to create coating thicknesses equal to or greater than those creatde using CVD using PVD. Furthermore we are now able to address the flaws of inside diameter processing of PVD coated dies. At Wadayama Seiki, based on predictions of the coating thickness we are able to control the size of the inside diameter through polishing (mirror polishising).

- ■ Multicomponent

- One can utilize every type of metal or metal alloy as a raw material when using the PVD method, so compared to CVD, in which only gases can be used, the number of raw materials one can choose from is significantly higher.

Special Characteristics of Coating

Preaparations for the most suitable coating can be made for all types of molds.

The characteristics are listed below.

If you are unsure of which type of coating best suits your needs, we can conduct a study on the mold that you currently use. Based on that study we can recommend the most suitable type of surface treatment.

| Treatment Code |

Main Component |

Color Tone |

Standard Thickness [μm] |

Hardness [Hv] |

Heat Resistance [℃] |

Coefficient of Friction [μ] |

Characteristic | Abrasion resistance |

Surface Roughness |

|---|---|---|---|---|---|---|---|---|---|

CRN

|

CrN系 | Silver | 4-6 | 1800 | 600 | 0.5 | Highly consistant performance | -- | - |

TCN

|

TiN TiCN系 | Gold | 3-5 | 2200 | 500 | 0.5 | High versatility that compliments all types of molds | - | - |

ALM

|

TiAIN系 | Dark purple | 4-6 | 2800 | 900 | 0.7 | Balanced with a high oxidation resistance and long track record of being used on dies | + | + |

TSP

|

TiSiN系 | 赤銅 | 3-5 | 3800 | 950 | 0.8 | 高圧縮応力、バランス型。ダイスへの適応実績も豊富。 | ++ | + |

ALC

|

AlCrN系 | Indigo blue | 2-4 | 3300 | 1000 | 0.7 | Higher wear resistance that is suitable with both steel and carbide substrate | +++ | + |

ALZ

|

AlTiCrN | Black ash | 4-6 | 3300 | 1000 | 0.7 | Higher wear resistance that is suitable with both steel and carbide substrate | +++ | + |

MSP-Q

|

AlCrN系 | 黒青 | 2-4 | 3400 | >1000 | 0.6 | ALZよりも面粗度、耐摩耗性に優れる | ++++ | ++ |

MSD

|

DLC系 (ta-C) | 虹 | <1 | >6000 | 400 | 0.1 | 水素フリーDLC、非鉄材加工で耐摩耗、耐凝着性に優れる | (++++) | + |

The following options are available. As for alternative specifications please contact us separately.

- Coating Removal

(Grinding is possible with carbide) - Microblast

(Not possible with carbide) - Plasma Nitridization

(Not possible with carbide)

Hardness and Oxidation Temperatures for all Coatings

CRN

TCN

ALM

TSP

ALC

ALZ MSP-Q Cemented

Carbide HSS

ALZ MSP-Q Cemented

Carbide HSS

Coating Evaluation Example

Number of shots

- CVD-TiCN

-

ALCrN

(Outside processing)

- TEST1

- TEST2

- ALM

- TCN

- ALC

- Tool

- #6 Die Pin

- Form of Life

- Tip Bearing with Vertical streak abrasion

- Process

- draft, thickness 11mm

- Pin diameter

- Φ8.4

- Material of pin

- VM30

Copyright ©2026 Wadayamaseiki. All rights reserved.